1060 H14 Aluminum flat bar

PRODUCT DETAILS

Product introduction

1060 H14 Aluminum flat bar is a kind of aluminum product. The casting process of aluminum rod includes melting, purification, impurity removal, gas removal, slag removal and casting.

Aluminum rod has special chemical and physical characteristics, not only light weight, strong texture, but also has good ductility, electrical conductivity, thermal conductivity, heat resistance and nuclear radiation resistance, is an important basic raw material for national economic development.

Aluminum rod casting includes melting, purification, impurity removal, gas removal, slag removal and casting processes.

Aluminum rod casting process includes melting, purification, impurity removal, gas removal, slag removal and casting process. The main process is:

(1) Ingredients: According to the specific alloy grades that need to be produced, the addition amount of various alloy components is calculated, and various raw materials are reasonably matched.

(2) Smelting: the prepared raw materials are added to the melting furnace according to the process requirements, and the impurities and gases in the melt are effectively removed by degassing and slagging refining.

(3) Casting: Molten aluminum is cooled into various specifications of round casting rods through deep well casting system under certain casting process conditions.

Aluminum rod production line is roughly divided into casting workshop, mold workshop, extrusion workshop, aging workshop, packaging workshop, finished product warehouse, aluminum rod warehouse.

1060 Chemical element content (%)

|

Element |

Al |

Fe |

Si |

Mn |

Cu |

Ti |

V |

Zn |

Mg |

other single |

|

minimum value |

99.6 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

maximum value |

- |

0.35 |

0.25 |

0.03 |

0.05 |

0.03 |

0.05 |

0.05 |

0.03 |

0.03 |

Data presentation

|

Product name |

Aluminium flat bar |

|

Alloy |

1050/1060/1070/1100/2A06/2A12/3003/3004/3105/4A01/ 5A06/5052/5056/5083/5754/5A06/6061/6063/6201/7005/7075/ |

|

Temper |

H111/H112/H12/H16/H18/H24/H32/H14/T3/T4/T5/T6/T8 |

|

Diameter |

10mm-400mm ,Support customization |

|

Length |

Support customization |

|

Type |

OEM/ODM |

|

Processing Service |

Cutting, surface treatment, rough bending, hardening, surface painting, forming |

|

Standard |

ASTM,AISI,JIS,GB, DIN,EN |

|

Certificates |

ISO, SGS,BV |

|

MOQ |

1 TON |

|

Delivery time |

Future Goods: 10-20 days, Ready stock: 5-10days |

|

Packaging |

Seaworthy Wooden pallet ,Wooden case,Aluminum case |

|

Application |

Transportation, construction, machinery and equipment, decoration, industrialization, etc |

|

Payment Terms |

T/T, L/C etc |

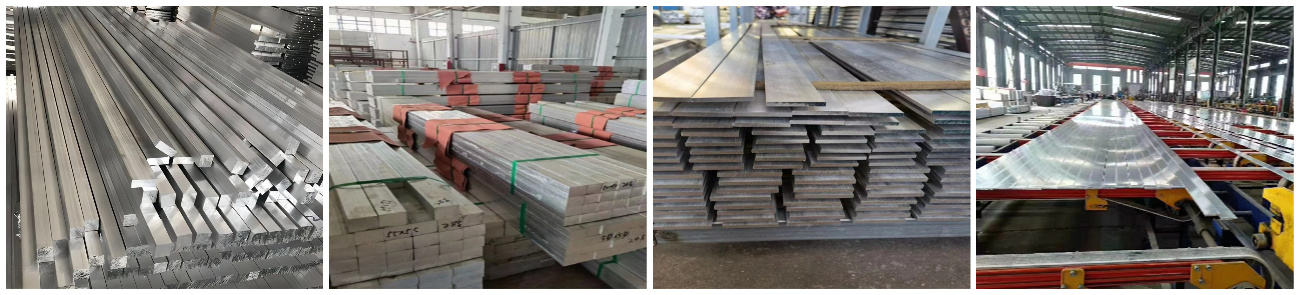

Warehouse storage

In order to meet the needs of customers "small batch, multi-specification, to spot" (the minimum order quantity of a single specification is 1 ton), we have been committed to 1-8 series aluminum sheet aluminum sheet, aluminum coil, aluminum foil, aluminum tube and other aluminum products R & D, production and sales. Annual inventory of more than 3,000 tons, complete brand specifications, truly meet customers "one-stop" procurement.

Packaging and shipping

In today's fast-developing information age, with a strong logistics system, we realize the three fast advantages of "fast response, fast shipment, fast logistics", and a professional marketing team, so that global customers in the pre-sale, sale, and after-sales process.

Application area

Aerospace, transportation, packaging, electronic home appliances, printing, building decoration aluminum and other 6 series of pillar products. The company covers aluminum product development and research, design and production, sawing, punching, milling and other deep processing. Mold making workshop, aluminum extrusion workshop, oxidation workshop one-stop production, quality won the trust of users, adhering to the "customer first, quality first".

Timely response

Source manufacturers, 0 links direct supply, 3 module production lines, daily output of 80,000, sufficient production capacity fast delivery. Stable and sustainable production, ensure quality and production efficiency.

The service team provides customers with new specifications supporting the use of the plan to answer questions, a full range of sample delivery services, use experience, timely return visits, so that customers have no worries. Contact information on the right, come and get the free quotation!

Customer visit

We warmly welcome new and old customers from home and abroad to visit and negotiate!

HONOR CERTIFICATE

FACTORY ENVIRONMENT

Factory

Factory

Factory

Factory

Factory

Factory

Factory

Factory

Factory

Factory

Factory

Factory

RELATED PRODUCTS

GET A FREE QUOTE